Uncategorized

Oak Timber Care: Sanding and Finishing Tips for Long Life

Oak timber is one of the most popular woods for woodworking because of its strong grain, rich color, and classic charm. But even the strongest hardwood needs the right care to stay in good shape. Sanding and finishing are important stages that will decide how long your oak timber will last, whether it’s new or old.

If you don’t take care of it, oak can quickly become dull, cracked, or twisted. This article gives you practical, honest, and simple advice on how to care for oak timber the way it should be.

Why Oak Timber Needs Special Care

Oak timber is known for being dense and long-lasting, but that hardness comes at a cost: you need to be patient and know how to deal with it. Oak doesn’t overlook bad sanding or a hurried finish like softer woods do. Because it is a hardwood, its densely packed grain keeps out moisture and dents, but only if the surface is well prepared.

If oak timber is left unfinished, it can dry out over time, which might cause it to shrink or crack on the surface. Finishing is like armor; it protects the timber from the inside out and keeps the beautiful grain visible. The USDA Forest Products Lab says that properly finished oak timber can endure decades longer than unfinished timber in the same conditions.

Choosing the Right Sandpaper for Oak Timber

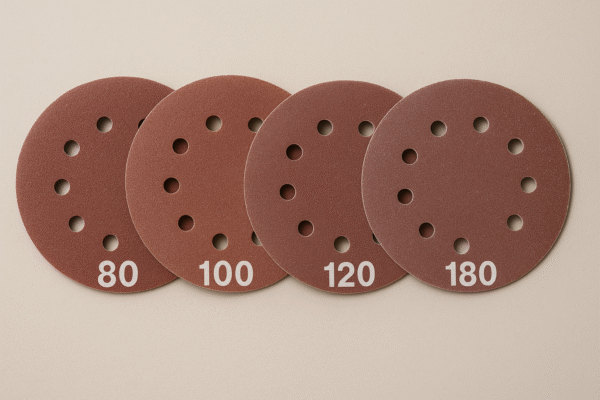

Before you select any old piece of sandpaper and start grinding, remember that oak timber needs a gentle but strong touch. Coarse grit, like 60 or 80, will rip the grain on timber planks, leaving scratches that are still there after sealing. The best grit for oak timber is usually between 120 and 220.

You should rough up the surface a little bit before finishing if the timber has been planed, especially if it has been planed and smoothed out by machine. Making the grain suitable for sealants is what smooth means, not always ready.

A sanding block helps woodworkers maintain their strokes even, which is especially important for oak timber that has been trimmed to size for furniture or cabinets. Machine sanding is quicker, but hand sanding provides you more control and lowers the risk of destroying the grain when you need to be precise.

Understanding Moisture Content and Oak’s Behavior

A lot of people overlook this: oak timber is still a natural substance after it has been chopped. It reacts to what is around it. If you don’t dry your oak timber correctly before finishing it, it can distort or split over time. Moisture meters are cheap and simple to use. They let you know if your planed timber is ready. Before you put on any finish, the timber should have a moisture content of 6% to 8%.

According to the National timber Flooring Association, timber that is very wet before being sealed is 2.5 times more prone to develop problems like cupping or splitting in the first year. That risk isn’t worth it.

Conclusion

People who prefer oak timber get good things from it. If you sand and finish it the appropriate way, it can last a lifetime or longer. The idea isn’t to work the timber too hard, but to learn about it. This includes letting it dry, sanding it carefully, picking a finish that fits the wood’s function, and then taking care of it gently. It’s not hard, but you need to be patient.

Every piece of oak timber has a tale to tell, whether it’s a plank, planed wood, or timber cut to size. If you take care of it, it will last for a long time. If you take the time to do it well, hardwood timber may provide you with that kind of value.